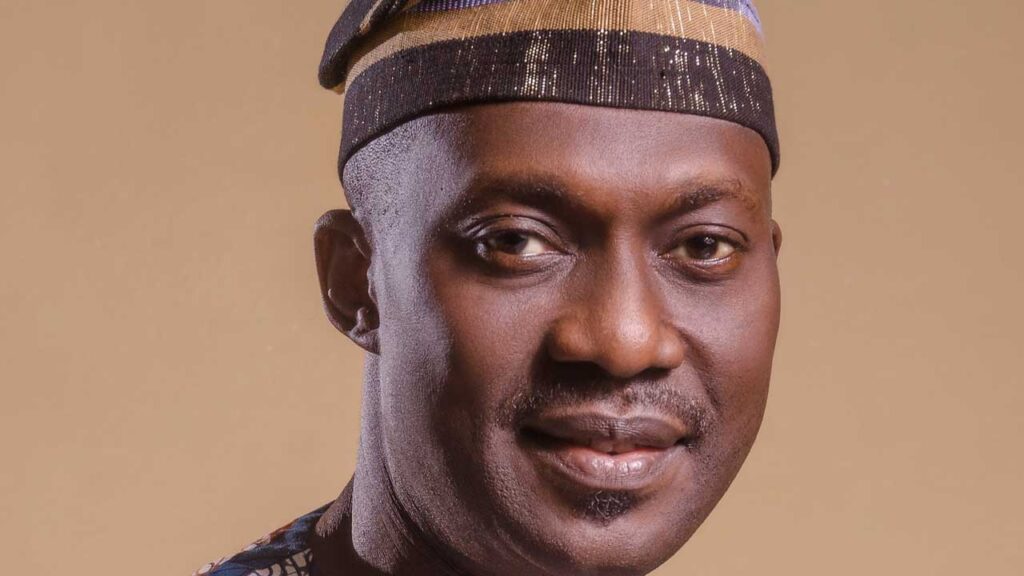

The Manufacturers Association of Nigeria (MAN) has predicted a challenging year for businesses, especially during the first half. In its manufacturing outlook for the year, MAN’s Director-General, Segun Ajayi-Kadir, revealed that manufacturing growth rate nosedived to 0.48 per cent in Q3 2023 as against 2.4 in 2021, adding that the first half of this year would be challenging, with a lean possibility of recovery from the third quarter.

He, however, said the envisaged recovery is highly dependent on the deployment of policy stimulus supported with a synthesis of domestic growth driven, export focused and offensive trade strategies; which will promote resilience, steady growth and ensure that the sector gains meaningful traction in the later part of the year.

Adding that the sector is struggling globally, challenged by key macroeconomic variables and externalities, he said this has led to dwindling growth.

“This is evidenced by the manufacturing growth rates in China, USA, and South Africa. The World Bank reported that the manufacturing sector in China declined from 8.7 per cent in 2021 to 4.8 per cent in Q3 2023; in USA, the sector performance dwindled to -0.9 per cent in Q3 2023 from the 6.8 per cent recorded in 2021 while South Africa also recorded a decline to -0.17 in Q3 2023 from 6.7 per cent of 2021, similar to what we have all over Africa,” he said.

Drawing from likely economic dynamics and in the light of the aforementioned, he revealed that their projections for the sector this year include clarity on the actual and specific policy direction and priority areas of the current administration, especially around deepening industrialisation, and “we look forward to engaging Government in this regard. Hopefully, Government will see the manufacturing sector as the key driver of sustained economic growth and give it the priority it deserves.

“In 2024, sectoral real growth is expected to hit about 3.2 per cent; contribution to the economy will most likely exceed 10 per cent and the Manufacturers’ CEOs Confidence Index is predicted to rise above 55 points thresholds by the end of Q4 2023. Average capacity utilisation will still hover around the 50 per cent threshold as the forex-related challenges and high inflation rate limiting manufacturing performance may linger until mid-year.”

He also added that the sector may experience a meagre improvement in manufacturing output as forex and interest rates-related challenges are expected to subside from the third quarter, while higher manufacturing output is envisaged from the beginning of the third quarter of the year as government disburses capital provisions of the budget to abandoned, ongoing and new capital projects with expected special preference for locally made products.

He also said the ongoing concessions of seaports, airports and roads may also provide opportunities for the cement sub-sector and contribute to infrastructure upgrade needed to enhance manufacturing productivity and reasonable stability in the monetary policy ambience as the apex bank reverts to playing its conventional roles and deliberately improves forex supply to the productive sector for import of inputs not available locally.

“The results of the emerging upward surge in global oil prices, domestic oil and gas production, local refining of petroleum products and projected gains of exchange rate unification will promote stability in the forex market and impact manufacturing positively from the second half of the year. This will lead to reduction in the pressure on demand for forex and improve the inflow of export proceeds from oil and gas. Also, ongoing tax reforms and the envisaged bank recapitalisation will frontally address the challenges of multiple taxation and poor access to credit that have continued to limit manufacturing sector performance, if successfully implemented.

“Expect dynamic implementation of the Electricity Act 2023, which will increase private investment in renewable energy, enhance energy efficiency and improve electricity supply to the manufacturing sector. The improved electricity supply will ameliorate the issue of inadequacy, reduce the disruptions occasioned by frequent outages and in turn improve energy security. In broad terms, the year may start on a tough note for manufacturing but may end with some measured improvements because the envisaged policy reforms, improved commitment to domestic production and general positive outlook seems favourable for the sector.”

To improve the sector this year, he recommended that the government expend cost saving from fuel subsidy to deploy a bouquet of production focused policies, backed with more structural measures to combat the peculiar inflationary pressures from insecurity, energy and transport cost. He also urged that the power sector be overhauled and incentive investment in renewables given to boost electricity generation and promote energy-cost efficiency. “Government should lead by example and give priority to patronage of made-in-Nigeria products in all its purchases and for all government contracts and projects. Government should mandatorily upscale patronage of made in Nigeria products by deliberately reducing the excessive reliance of the country on imported products. The three tiers of Government should enforce the implementation of the Executive Order 003 in same for their ministries, departments and agencies.

He urged the government to encourage local sourcing of raw materials through comprehensive and integrated incentives to address the challenges of low productivity and imported inflation; utilise the 2024 budget to sustain effort at improving infrastructural developments, especially in strategic industrial hubs to reduce operation and logistics cost and promote competitiveness. Encouraging sub-national governments and private investors to leverage the opportunities provided by the Electricity Act 2023 to improve energy security in Nigeria, he said government must maintain all measures to boost liquidity and transparency in the forex window even as the backlog of $7 billion forex obligations is being cleared.

He further admonished that the floating exchange rate system must be managed within an acceptable lower and upper bound, pending the actualisation of a net-exporting economy aspirations while FX and credit allocation to manufacturers must be prioritised. “Reduce the number of BDCs into large and well-established operators to curb their excesses and untoward operations through effective management and supervision. Encourage inflow of foreign direct investment into pre-determined and domestic production-enhancing businesses. Should intentionally guide diaspora remittances into non-oil sectors, especially manufacturing to aid forex inflows and curb rising inflation.”

Also, the CBN should intensify its collaboration with the fiscal authority; Federal Ministry of Finance and by extension the Tariff Technical Committee (TTC) for proper policy alignment on the appropriate HS Codes for items that Nigeria has sufficient capacity to discourage importation and save scarce foreign exchange. The apex bank should allow FX access for importation of vital industrial inputs that are currently not available locally and subject them to backward integration policy that gives priority to a predictable sunset clause.” Offering to be part of a monitoring and evaluation team to ensure that government gets value for incentives offered to achieve this objective, he urged the CBN to develop a sustainable framework to channel credit interventions into the manufacturing sector, outside the direct intervention. “Additionally, it should mobilise commercial banks to intentionally provide long term single digit interest loans to the manufacturing sector to fast-track the actualization of a $1 trillion dollar economy,” he concluded.